Computer Vision

Advantages

Versatile

Flexible

Reliable

Optimized for steel mills

Quick installation

Customizable

High accuracy

Multiple applications with single camera

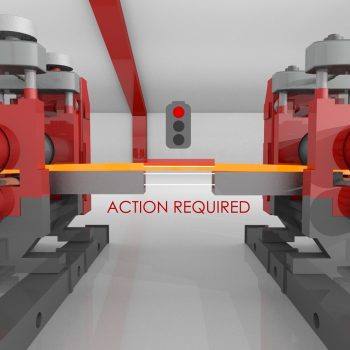

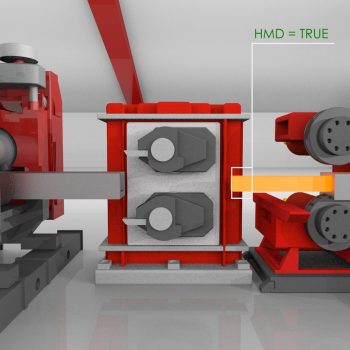

Detection

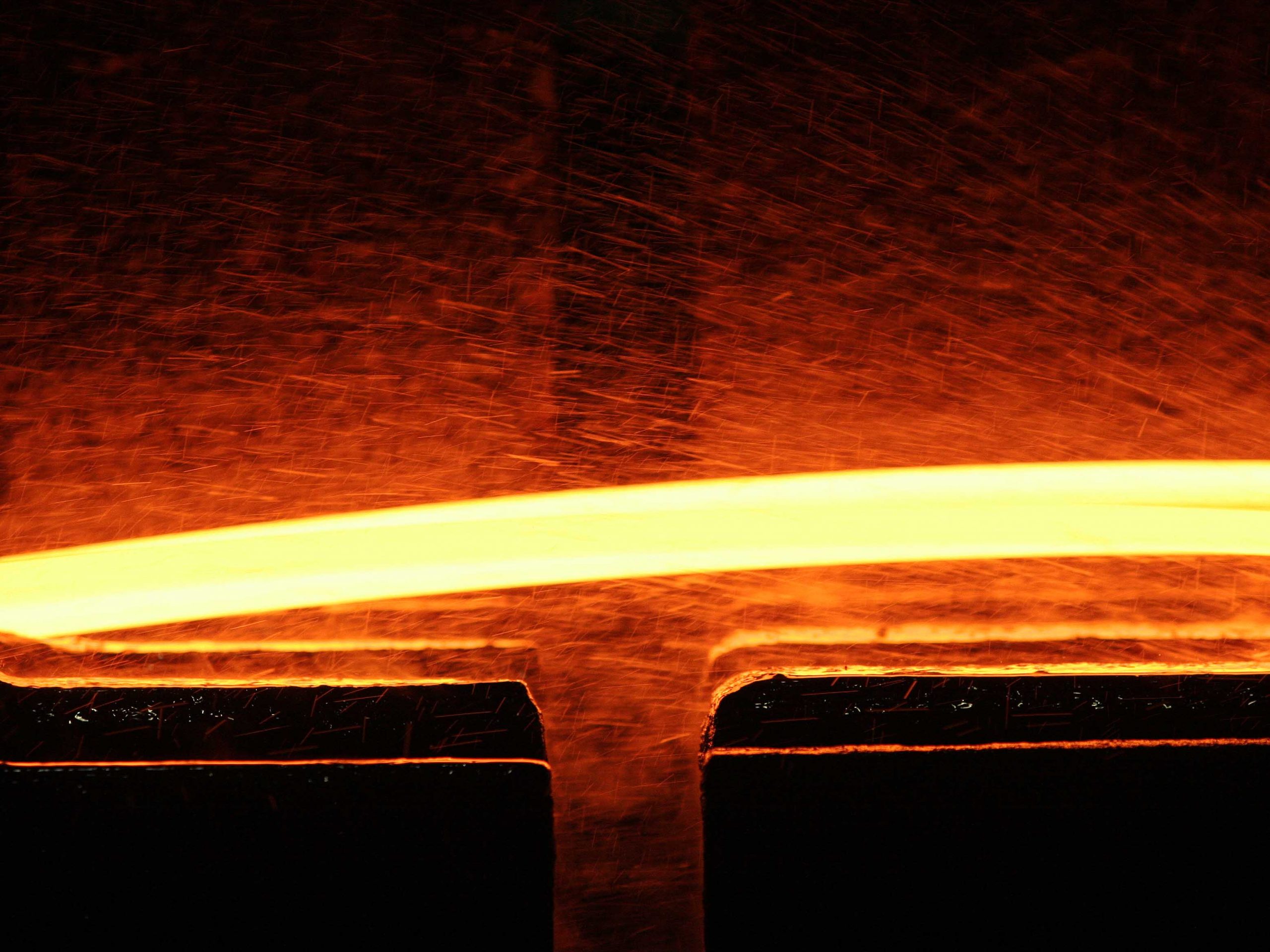

Russula’s Computer Vision is used for hot metal detection, push detection and cobble detection applications.

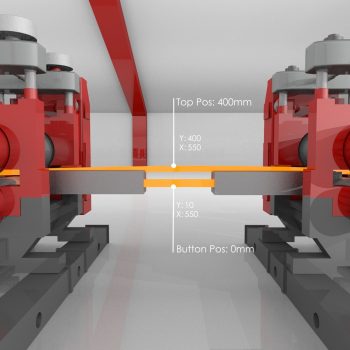

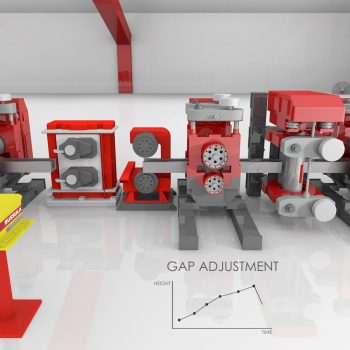

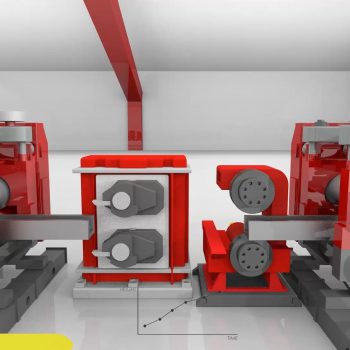

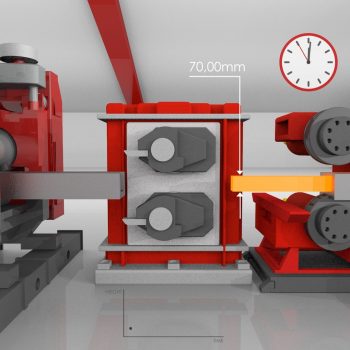

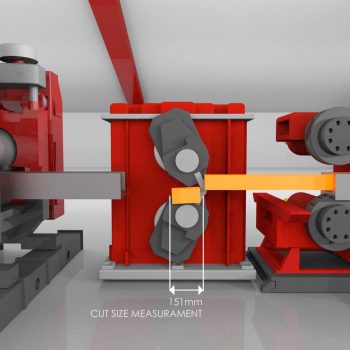

Measurements

Loop height, cut size and synthetic push measurements are all precisely measured and communicated in real time to the mill PLCs.

Triggers

Computer vision algorithms identify events which can trigger external equipment, communicated through digital outputs or through industrial field buses.

Image Log

The Russula Computer Vision solution bundles together photos taken at high speeds. This burst shooting function can be manually or automatically triggered. Computer Vision helps the operator’s troubleshooting and confirms rolling conditions.

Customized

Additional detection and measurement algorithms can be customized according to our customer’s requirements. Our experts will analyze the viability and develop the new algorithm for each and every task.

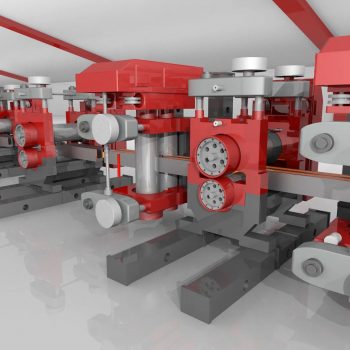

Process characteristics, image scene, lenses, image sensor, and other factors are carefully selected to achieve the accuracy our customer’s require. Russula Computer Vision is currently used in several steel mills, proving day by day its reliability and adaptability.

RUSSULA'S

Computer Vision for Rolling Mills

Hot Metal Detection, loop height, shear cut, stand gap and cobble detection can be reliably measured with our computer vision solutions.