Gerdau Whitby improved reheat furnace safety and reliability

In 2017, Russula upgraded the electrical and automation system of the 120 ton/hr walk-ing beam reheat furnace at Gerdau in Whitby Canada. Furnace safety and reliability improved after the upgrade by changing the current natural gas distribution, safety system and furnace controls.

The 120 tons/hr gas reheat furnace for the bar mill is divided into 7 heating zones. The current control system is a combination of a Modicon Quantum PLC and Honeywell loop controllers. Before the revamp, the burner light up operated manually and there was no flame supervision.

Scope of Supply

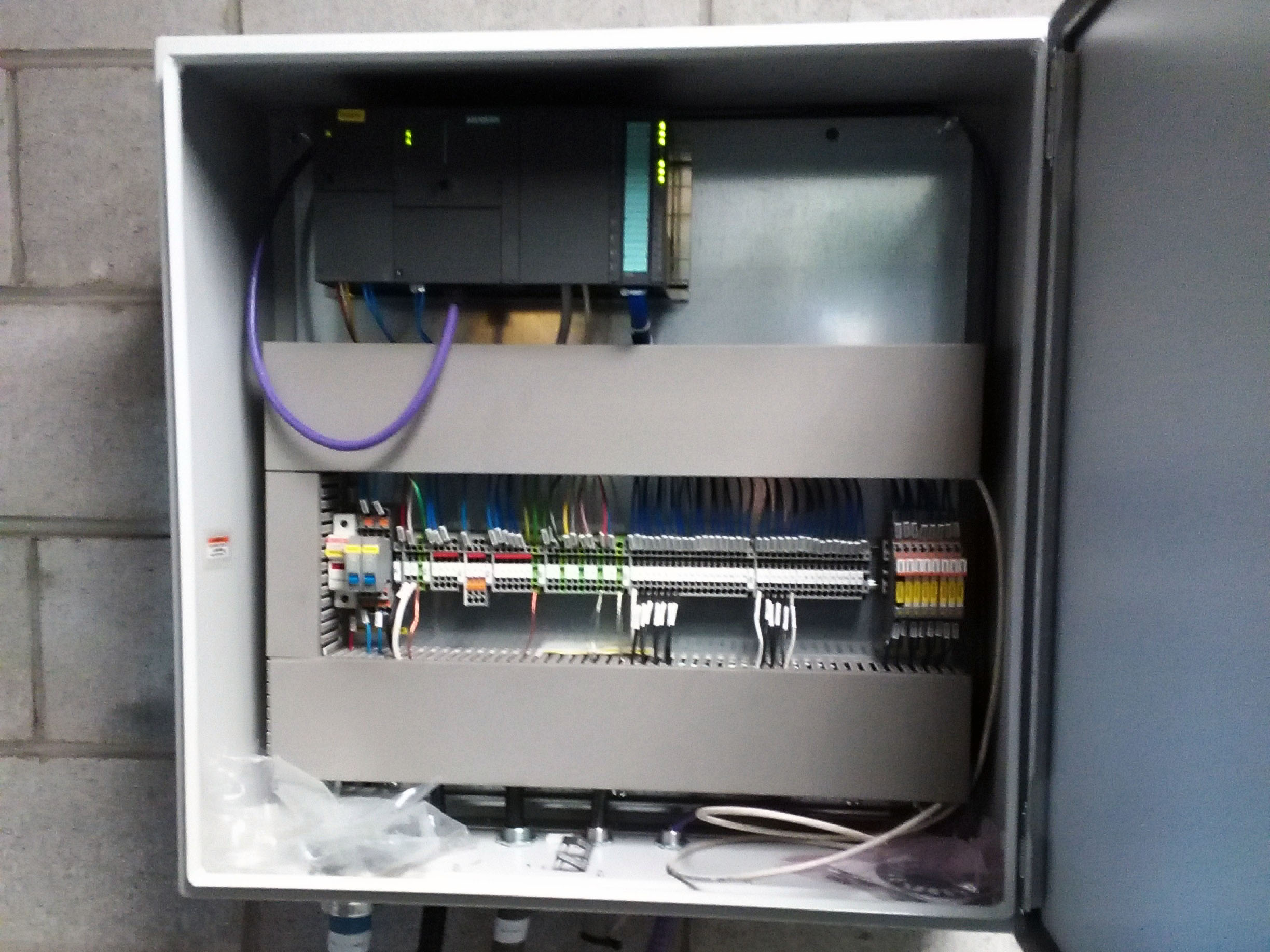

Russula supplied all the electrical equipment and control software necessary for the Whitby reheat furnace to comply with international safety standards. In a joint collaboration with Industrial Combustion and Control Specialists from Bloom Engineering, together Russula and Bloom techncial experts ensured that all the changes to the equipment, the furnace natural gas distribution, electrics and automation complied with Technical Standards and Safety Authority (TSSA) requirements. Located in Toronto, TSAA is charged with promoting and enforcing public safety.

For the Gerdau Whitby reheat furnace upgrade, Russula included a combination of software, hardware and services.

Russula’s reheat furnace control has been continuously developed and optimized from application to application. Level 1 Heating Control and Level 2 Furnace Optimization were implemented on the Gerdau Whitby reheat furnace. Based on heating strategy tables and delay multipliers, Level 2 Furnace Optimization efficiently manages the reheat furnace downtime, both planned and unplanned, permitting a significant reduction in gas consumption per ton of steel produced.

Results

During August and September 2017, the Gerdau Whitby and Russula engineering team commissioned the new automation system during a planned shutdown. Most of the wiring and piping was completed prior to the shutdown in order to start production again as quickly as possible. During the shutdown the new safety and control system was installed. The mill started back up to full production in September.

Russula has a long standing relationship with the Gerdau Whitby plant. In 2004, Russula upgraded the bar mill with a new automation system, operator desks and an iba high speed data acquisition system. The upgrade resulted in an 8% production output increase. Existing mill drives were updated with new digital "front-ends", a cost effective method of bringing older drives up to modern standards of performance and diagnostic capabilities.

About Gerdau Whitby

Located in Whitby, Ontario, Canada, the mill produces angles, channels, round, square reinforcing and flat bars. The goal of the upgrade was to improve furnace safety and reliability.