Planta de tratamiento de agua para la acería y tren de laminación en condiciones climáticas extremas

Severstal (currently Abinsk Electric Steel Works LTD) chose Russula to supply a new water treatment plant for the new long product mini-mill at Balakovo in the Saratov region of Russia. The next-generation mini-mill produces more than 1 million tons of long products per year. Russula accepted the challenge of designing and constructing a process water treatment plant that endures temperatures of - 40°C (-40°F).

“Russula is the only solutions provider that has developed a water treatment plant specifically to treat steel plant water. We provide the entire, fully engineered package that provides long-term benefits.”

Juan Kessler, Product Manager for the Water Technologies Division

Scope

Russula provided a state of the art water treatment plant to treat 9,675 m³/hr (42,598 gpm) of water critical to the steel production process.

Plant Layout

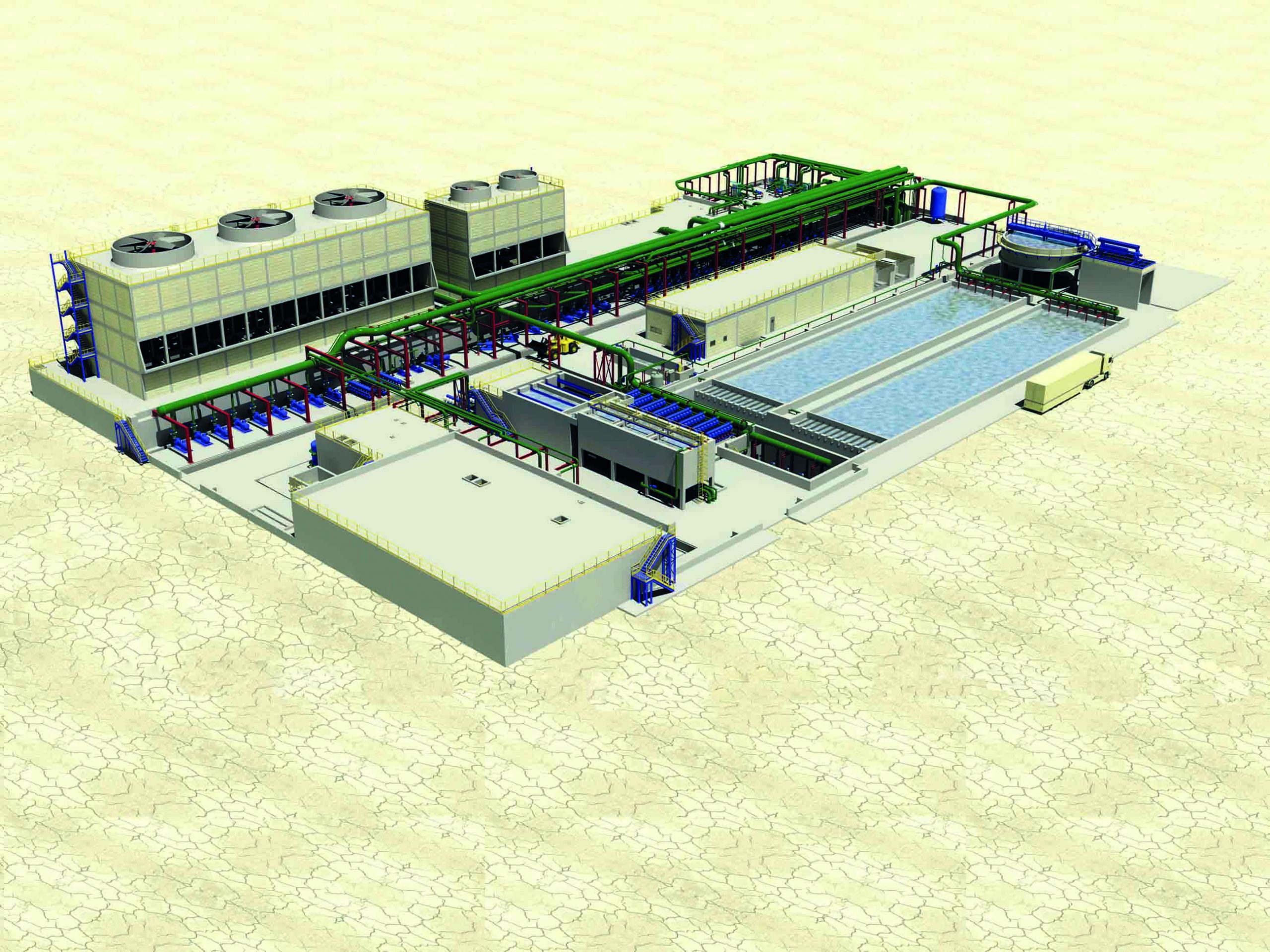

The plant consists of a contact water circuit for the continuous caster and rolling mill, a non-contact circuit for the EAF, ladle furnace and rolling mill dedusting plant and a make up water circuit, which treats water from the River Volga. It has been designed to ensure maximum viability, taking a high-end engineering approach to guarantee the water quality fulfills steel production requirements.

There are three main circuits: the noncontact water circuit, the contact water circuit and the makeup water circuit. The non-contact water circuit, for instance, isn't subjected to all the treatment steps necessary for the contact water circuit. The non-contact water circuit, with a 6,470 m³/hr volumetric flowrate, is for cooling the EAF, ladle furnace, continuous casting molds, ladle furnace, reheat furnace and rolling mill fume dedusting plant. For the cooling system Russula included cooling towers, plate heat exchangers, and ring filtration as a preventative system to retain small particles.

Technology

Proprietary water technologies that included ring filters, decanting basins, plate heat exchangers, a thickener tank, cooling towers, bridge scrapers, skimmers to remove oil and grease, filter press and metering pumps offered a comprehensive solution to recover and recycle the water.

The 3,205 m³/hr contact water circuit is for the continuous caster and rolling starts at the scale pit, which removes particles that have a size equal to or greater than 200 microns. The density difference between the water and the scale, makes the larger heavier particles deposit on the bottom of the scale pit to be removed later. Afterwards the water continues to the longitudinal decanters, where small particles are removed by entrainment.

The coarse particles that fall to the bottom of the longitudinal decanters are collected by a dual function bridge scraper and are pumped to the sludge thickener tank and press plate filter press. The grease and oils remaining on the surface are swept by the upper part of the bridge scraper and guided to the oil skimmer.

The clean water then passes to the ring filters, which removes those particles having a density greater than water that have passed through the scale pit and decanters. Finally, the filtered water is pumped to the cooling towers, where it is cooled, before it recirculates back to the bar mill.

The 4,000 m³/h makeup water circuit is designed to receive the river water at a station, transport the water to the plant, clean the water, treat with chemicals and finally cool the water. The water intake is from the channel near the Central Heat and Power Plant 4 in Balakovo. In addition, rain and melt water from the region will discharge into a rain water tank and after settling is used to recharge the system for water recycling.

The water treatment plant is fully automatic with a separate a Siemens S7 – 400 PLC and HMI that is integrated with the mill control system. The ABB ACS800 variable frequency drives regulate water flow for the scale pit, longitudinal decanters, for both the contact circuit as well as the non-contact water circuit.

Russula supplied all low voltage distribution with removable panels for the circuit breakers and 10 kV medium voltage switchgears and power transformers. The MCCs, were provided with communication through intelligent relays using Profibus, instead of the typical control cables to connect the PLC's to the MCC's. This resulted in large project savings, minimizing cables, mounting materials and wiring time.

Project Execution

In the span of less than one year, Russula delivered the water treatment equipment, pumps, piping and cooling towers to Severstal's long product mill in Balakovo while it was under construction. To ensure the appropriate conditions for equipment storage and timely delivery to the assembly site, imported equipment was unloaded directly at the construction site for temporary storage.

During the course of the startup, specialists from Russula checked the quality of the installation for the water pipelines, automatic control systems and monitoring equipment. All civil work, equipment installation and assembly were supervised by Russula's Chief Engineer.

The Balocovo new generation mini-mill started up in the second half of 2014. It has an annual capacity of 1 million tonnes of profiled iron for building materials (reinforcement, angle, channel) and produces a range of 40 different products.