Gusa Nordeste pone en marcha la primera planta de acero verde del mundo

At the end of 2015, Gusa Nordeste, part of the Ferroeste Group, commissioned its steelmaking plant. Located in the city of Açailândia, in the western part of the Maranhão state in Northern Brazil, the new melt shop adds 420,000 tons per year of billet production to Brazil’s steel sector.

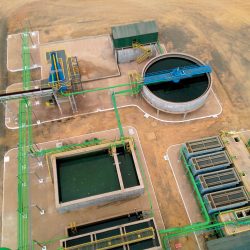

Russula supplied the complete water treatment solution, which consisted of both pretreatment and process water treatment. From October 2015 on, a Russula engineering team was on-site to supervise the water trials. Hot commissioning began when the first billet was casted in Gusa Nordeste’s three strands CCM towards the end of December.

Russula successfully delivered the entire water treatment solution on schedule over a period of fourteen months. All of the equipment, basic and detailed civil, mechanical and electrical engineering, installation supervision, commissioning support and training were included in the scope of supply.

Optimize energy efficiency | Minimize water consumption

Russula’s water treatment solutions focus on two important aspects of green technologies: optimize energy efficiency and minimize water consumption. A lot of energy and water savings can be achieved by using efficient equipment and increasing the reuse of water.

In line with the Green Steel energy saving philosophy, Russula installed high efficiency motors driven by variable speed drives as required by rolling mill operations or motor power. The end result was a reduction in power consumption as well as the CO2 footprint. The water treatment plant is fully automated. By minimizing manual operations in auxiliary systems such as water plants allows operating personnel to dedicate more time to the steel production process.

Additionally, the water system was designed to recover as much blowdown and discharge water as possible. This reduces the consumption of water and chemicals required, which helps Gusa Nordeste to be less dependent on external water sources. Reducing water consumption is one way to cope with the global water crisis and protect the environment.

Scope of supply

The water treatment plant at Gusa Nordeste treats a total water flow of approximately 7,500 m3 / h. The make-up water treatment and the process water treatment are divided into three separate systems. Russula supplied all necessary mechanical and electrical equipment.

The mechanical equipment included prefabricated and painted piping, metallic structures and valves. The electrical supply consisted of medium voltage panels, transformers, a motor control center with circuit-breakers, instrumentation, PLC and remote peripheral units.

Water pretreatment

The Makeup Water System treats a raw water mixture from the Piquiá River and deep wells. The percentage mix depends on the seasons and weather conditions affecting the various quality parameters of the river water, in winter is generally a greater volume of water. The pretreatment system automatically adjusts to the water mix to maintain correct water quality throughout the year. Russula included the following main equipment within the makeup water system scope of supply:

The Scrubber Water System main equipment supply includes a sludge thickener tank, filter press and a novel spiral dewaterer. This technology is used for BOF sludge treatment and is based on open tank solids settling and a spiral for removing and dehydrating the product to be treated.

Sludge thickener tanker

Spiral dewaterer

Filter press

Process water treatment

The water purification system treats sludge that comes from the BOF. First, the water enters the spiral dewaterer and then falls by gravity into an open sludge thickener tank, where the solids are deposited. The sludge is then dewatered and compacted in the filter press to form bricks. These bricks can be reused in the manufacture of cement. The alliance between Masaveu and the Ferroeste Group produces composite cement from blast furnace slag, called “green cement”.

The non-contact water treatment for the meltshop, reheat furnace and rolling mill is divided into three closed circuits. To meet the strict requirements of water quality and temperature, all circuits have ring filtration and cooling towers, except for the meltshop circuit, which also includes heat exchangers. The water treatment system for the oxygen plant is also a closed non-contact water circuit and includes the same equipment and similar functions as the meltshop circuit.

The contact water treatment for the CCM and rolling mill is an open circuit based on Russula's four-stage process. First, decantation happens in the scale pit, where particles larger than 200 microns are removed by a clamshell bucket. Second, particles that pass the scale pit, can settle in the longitudinal decanting basins. Slude, oil and grease are removed by the bridge scrapper. Particles that have managed to pass through the decanting basins and have a density greater than that of water are remove in the ring filtration system. Once filtered the water is pumped to the cooling towers where it is cooled before recycling to the process.

A sustainable future

Russula supplied all the water treatment systems in a period of 14 months. It was an honor to partipate in the Gusa Nordeste sustainable project. This project was an emblematic example of how a steelmaking plant can improve energy efficiency by taking advantage of alternative non-fossil fuel technologies that significantly reduce CO2 emissions. In the global race to reduce CO2 emissions, the ABV sustainable technology project paves the way for other steel producers to begin adapting their plants to the best available technologies.