All News

21 March 2019

21 March 2019

In January 2019, Big River Steel awarded Russula a contract to supply the water treatment solution for Big River Steel's Flex Mill™ expansion that will double the hot-rolled steel production capacity to 3.3 million tons annually. Russula designed and supplied the 154,000 gpm water treatment complex for the first phase of Big River Steel, delivered in 14 months from the contract award date.

Do you like it?

12 March 2019

12 March 2019

Following the successful electrical and automation modernization of slitter no. 2, Novelis contracted Russula to modernize its cold rolling mill in Pindamonhangaba, São Paulo, Brazil. Russula won the automation project in October, 2018.

Do you like it?

7 March 2019

7 March 2019

Russula Corporation announces the appointment of Kalisankar Pattanayak as the new Automation Division Manager of Russula Automation and Engineering Solutions India Pvt. Ltd.

Do you like it?

27 February 2019

27 February 2019

Russula Corporation announces the appointment of Sharad Jha as the new Country Manager of Russula Automation and Engineering Solutions India Pvt. Ltd.

Do you like it?

5 February 2019

5 February 2019

Celsa Atlantic chose Russula to perform a mechanical upgrade that allows the plant to roll with 180 mm size billets on both the bar and wire rod mills.

Do you like it?

5 December 2018

5 December 2018

Elvira Martínez Fernández, Quality, Safety and Environment Director, answers our questions in this extensive interview.

Do you like it?

5 December 2018

5 December 2018

INSIDE RUSSULA is a series of extensive interviews with auspicious members of our team.

Do you like it?

29 November 2018

29 November 2018

29 November 2018

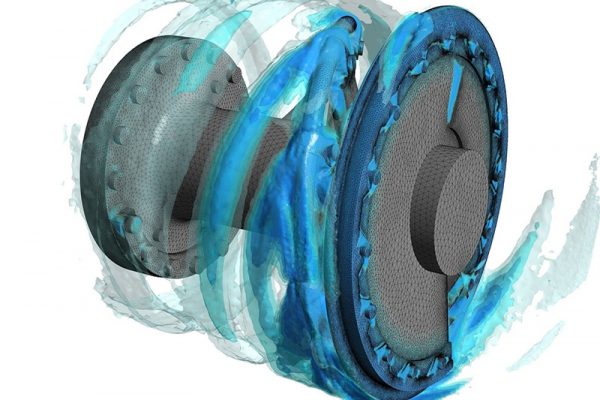

Russula has patented a new, simplified, laying head design that reduces maintenance downtime, noise and power consumption and extends the life of the equipment.

Do you like it?