Russula supplies 600,000 ton/yr combined bar and wire rod mill

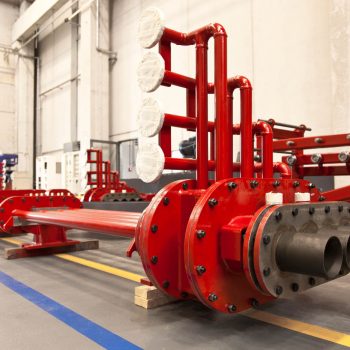

Russula supplied a 600,000 tpy combined bar and wire rod mill to Gerdau (formerly Silat), located in the region of Caucaia, Brazil. The 20 stand continuous mill has two outlets, one for 8-32 mm straight reinforcing bar with a slitting scheme and the other for 5.5-16 mm wire rod and rebar in coils. Billets are cold charged into a 90 ton/hr reheat furnace.

Russula provided the feasibility study, design, manufacture, installation and commissioning of the greenfield rod and bar mill, including its process water treatment plant. The main objective was to build a mill that has low yield losses, high utilization and low conversion costs. As a result, the mill layout, mechanical and electrical equipment supply is based on proven design concepts; constructing a mill that is easy to operate and maintain while minimizing spare parts.

Project Layout

The layout proposed was based on years of experience in long product rolling mills. Nothing was taken for granted, and all the details were designed from scratch and located with a single objective: simplify the daily operations and maintenance of the rolling mill.

Technology

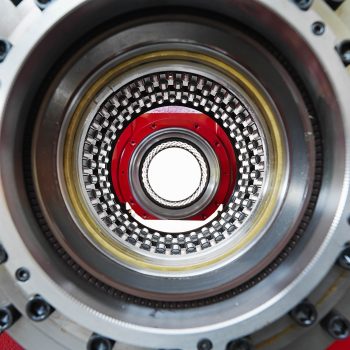

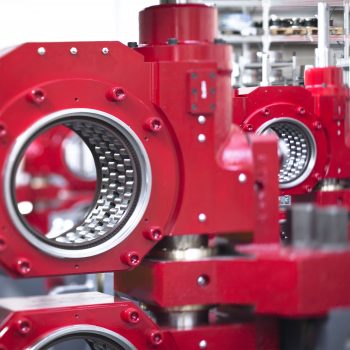

All rolling mill equipment was produced in Europe to better control the equipment assembly. The Russula mechanical team went through a strict selection process to ensure that experienced craftsmen with rolling mill process know-how guaranteed the equipment will have longer service life and reduced downtime.

- Walking Hearth Furnace - 90 ton/hr walking hearth furnace.

- 20 Stand Bar Mill

- Quenching System

- Cooling Bed - 102 x 8 meter cooling bed minimizes yield losses by reducing the number of cold shear crops per ton rolled.

- Cold Shear - Static shear with a nominal capacity of 650 tons and 1200 mm wide.

- Bundle Forming and Tying Area - Includes bar counting device and weighing and tagging station.

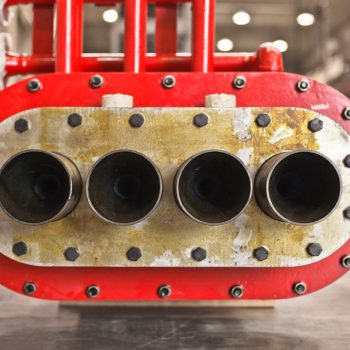

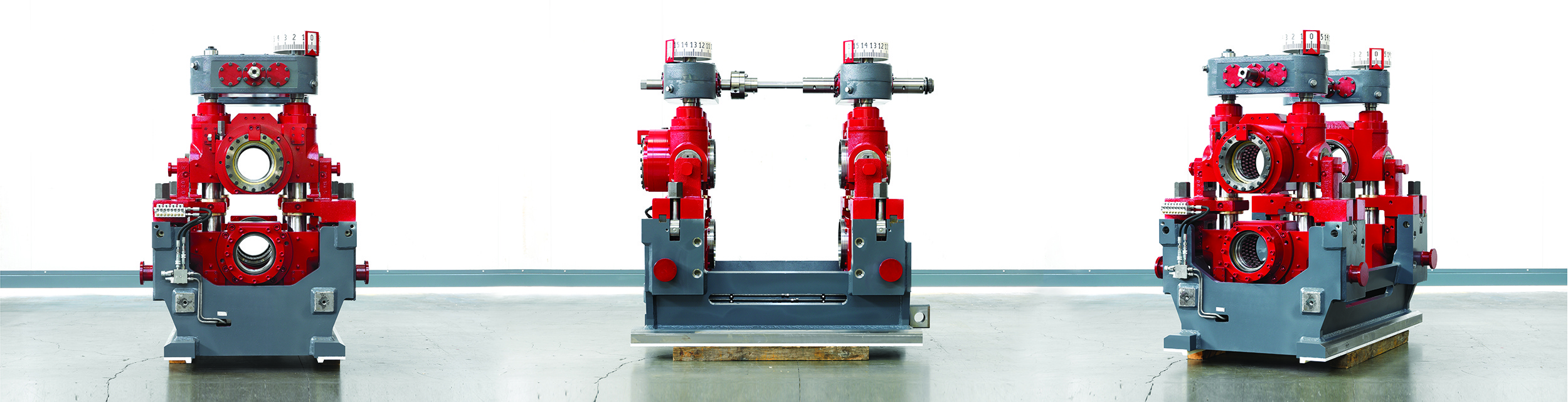

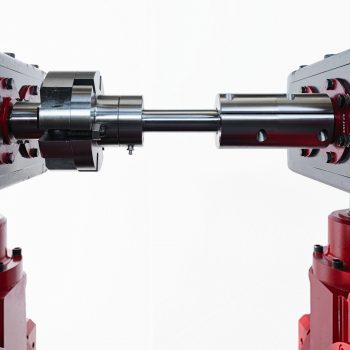

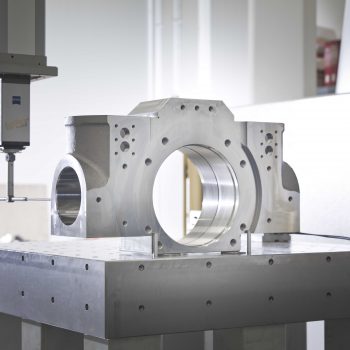

20 housingless stands

Russula supplied housingless stands to maximize mill utilization for long campaigns. To simplify operations only two roll neck sizes were used; 280 and 200 mm and two new roll diameters for each roll neck size. This minimized the number of spares needed for the stands. The roughing mill stands were supplied with the guides mounted on the rest bars from the roll shop while the intermediate and finishing stands were supplied with the guides mounted on pedestals. This feature minimized the time required for pass changes and improved alignment accuracy.The crop shears are located after stands 6 and 14. All the shears are start-stop to maximize accuracy and simplify maintenance. The divide shear after stand 20 can operate in rotary and crank modes depending on the speeds of the product being rolled.

Stands 1-14 operate with minimum tension control while the finishing mill operates with vertical loopers to minimize yield losses and add stability to the rolling process. Since 8, 10, 12 and 16mm rebars are rolled with a slitting pass design the last four stands are horizontal; special loopers and guiding equipment were installed in the finishing mill and quenching zone. The rest of the mill is in a H-V sequence to eliminate the need for twisting guides.

Project Execution

Leveraging all of its experience in the steel sector, Russula construction management team followed a framework based on communication, coordination and engineering techniques to increase efficiency during the construction process. In particular, prefabrication of piping saved considerable installation time and costs as well as the integration of multiple engineering disciplines into the construction of modules. A modular approach using prefabrication ultimately led to better quality and faster project execution time.

Results

On Tuesday, March 24th, the first billet was rolled on the bar mill. During the day, many billets measuring 130 mm x 130 mm x 12,000 mm were rolled and the 20 mm bars where discharged onto the cooling bed. Hot testing progressed quickly in the following weeks with 25 mm, 16 mm two slitting and 10 mm bars, using the 4 slitting scheme.